PC Series ISO 6150-C Safety Coupling Pneumatic Quick Coupling

Our ISO 6150-C Safety Pneumatic Quick Coupling is engineered for safe, secure, and efficient compressed air connections in industrial and workshop environments. Designed to meet the ISO 6150-C standard, this coupling provides automatic pressure relief to minimize hose whip and injury risk during disconnection, offering superior safety in high-traffic pneumatic systems.

Key Features

ISO 6150-C Standard

Fully compliant with the ISO 6150-C interchange standard for reliable cross-brand compatibility.

Safety Lock Mechanism

Two-step disconnection to release downstream air pressure before uncoupling – protects operators and equipment.

High Flow Performance

Optimized internal structure ensures low pressure drop and high flow rate for efficient tool operation.

Durable Construction

Manufactured from high-quality steel, brass or stainless steel, with corrosion-resistant surface treatment for extended service life.

Secure Connection

Positive locking mechanism ensures leak-free connection under demanding working conditions.

One-Hand Operation

Easy to connect and disconnect using one hand – ideal for fast tool changes.

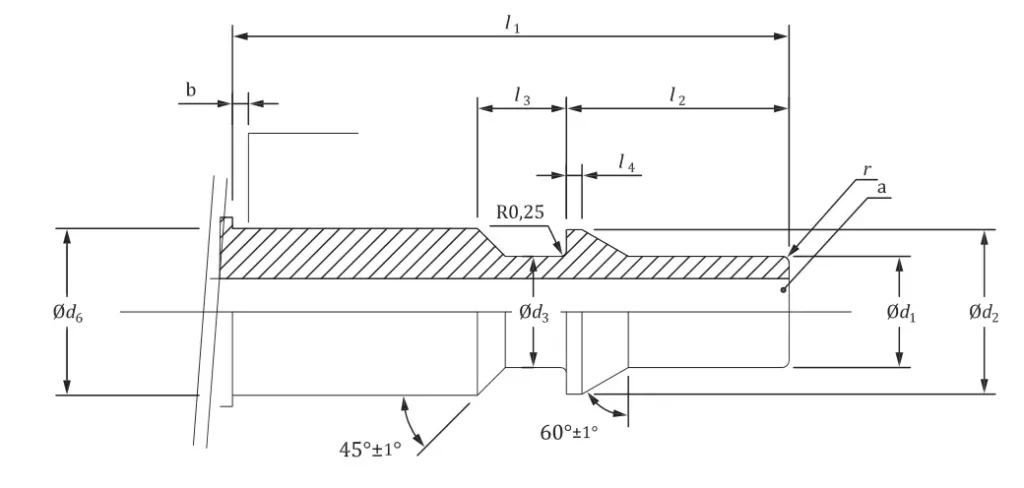

Dimensions

| Nominal diameter | d1 | d2 | d3±0.15 | d6 | l1 min. | l2±0.1 | l3 | l4±0.1 | r Max. |

|---|---|---|---|---|---|---|---|---|---|

| 8 | 5 | 7.4 | 5 | 7.5 | 25 | 10 | 4.5 | 0.7 | 0.3 |

| 10 | 7.5 | 9.7 | 7.4 | 10 | 27.5 | 12 | 7 | 0.75 | 1 |

| 14 | 11 | 13.7 | 11 | 14 | 36.5 | 17 | 9.5 | 1.5 | 1 |

| 17 | 14 | 16.7 | 14 | 17 | 41 | 18 | 12.5 | 2 | 1 |

| 27 | 23 | 26.7 | 23 | 27 | 61 | 27 | 16 | 2.5 | 2 |

As a manufacturer primarily focused on hydraulic quick couplings, we offer pneumatic quick connectors as customized products based on customer requirements.

For ISO 6150-C quick couplings, we’ve encountered inconsistencies between the standard documents and the dimensional data provided by some other manufacturers. For instance, while ISO 6150-C specifies a nominal diameter of 14 mm, some sources listed as DN8 such as TST from Europe, which can cause confusion during selection or interchange.

As an OEM supplier, we strongly recommend that customers confirm the key dimensions before placing an order—especially if compatibility with existing systems is required. Providing a sample for reference is the most reliable way to ensure accurate production and fit.

Applications:

- Pneumatic tools

- Air compressors

- Automotive workshops

- Manufacturing lines

- General industrial air systems