How to choose material

How to Replace Bobcat Hydraulic Quick Couplers

Bobcat machines, particularly skid steers, utilize quick couplings to efficiently connect and disconnect various attachments, enhancing versatility and productivity. These couplings come in different types, serving diverse needs and applications.

Replacing Bobcat hydraulic quick couplers can be a relatively straightforward process, but it’s important to follow the correct steps and take safety precautions to avoid injury or damage to your equipment.

Types of Quick Couplings

Flat Face Couplers

Flat face quick connectors are the most widely used in Bobcat equipment, usually 1/2″ body size and 1/4″ body size, with NPT and SAE threads, and bulkhead and other different designs.

ISO A Couplers

ISO A quick connectors are commonly used in agricultural equipment. Bobcat equipment can use ISOA equipment to connect agricultural accessories.

ISO B Couplers

ISO B quick connectors are used in many hydraulic system accessories. Many such quick connectors are also used in Bobcat equipment to quickly replace accessories.

how to replace bobcat quick couplings

Replacing Bobcat hydraulic quick couplers can be a relatively straightforward process, but it’s important to follow the correct steps and take safety precautions to avoid injury or damage to your equipment. Here’s a general guide to get you started:

Preparation

- Gather Equipment: You’ll need wrenches appropriate for the coupler sizes, rags, safety glasses, gloves, and replacement couplers with compatible seals. Check the Bobcat operator’s manual for specific wrench sizes and part numbers for replacement couplers.

- Safety First: Park the Bobcat on a level surface, engage the parking brake, and ensure the engine is off and cool. Release any pressure in the hydraulic system by engaging the boom controls and cycling them several times. Double-check that the system is depressurized before proceeding.

- Locate the Couplers: Identify the couplers you need to replace. Typically, Bobcats have quick couplers on the auxiliary hydraulic lines near the control levers for attaching attachments.

Replacement Process

- Disconnect Lines: Using the appropriate wrenches, loosen the couplers on both sides of the attachment lines. Be careful to capture any leaking fluid with rags to prevent contamination.

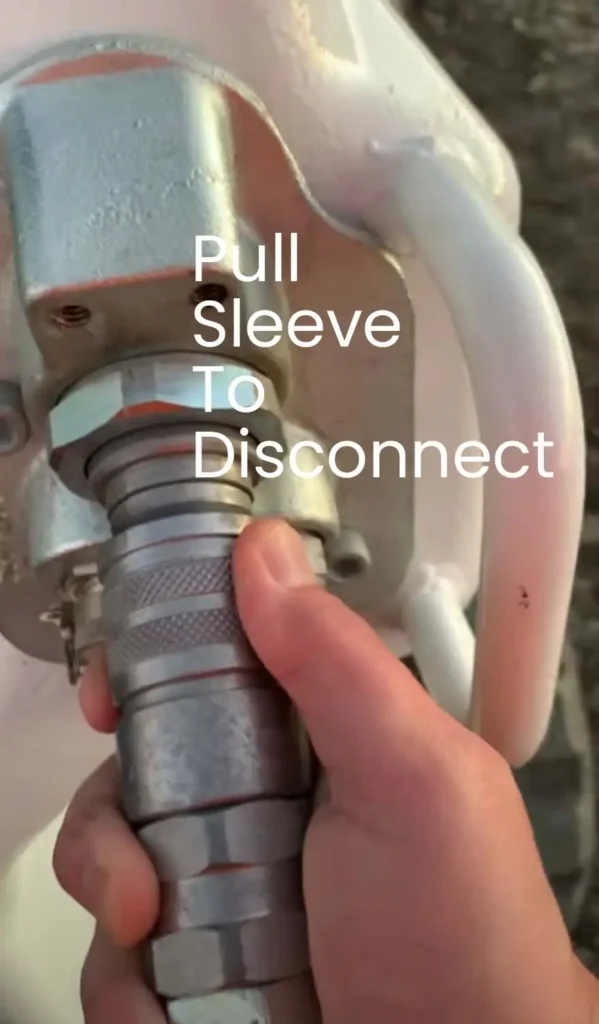

- Remove Old Couplers: Once the lines are disconnected, unscrew the couplers from the attachment and boom by turning the collar or sleeve.

- Clean and Inspect: Clean the connection points on the boom and attachment with rags to remove any dirt or debris. Inspect the threads and sealing surfaces for damage or wear. If worn or damaged, consider replacing the entire hose assembly instead of just the couplers.

- Install New Couplers: Apply a light coating of hydraulic fluid to the threads of the new couplers and screw them into the boom and attachment connections until hand-tight.

- Tighten Couplers: Use the wrenches to tighten the couplers snugly, following the specified torque values in the operator’s manual. Don’t overtighten, as this can damage the couplers or threads.

- Reconnect Lines: Reattach the hydraulic lines to the couplers and tighten the connections with the wrenches.

- Test System: Start the Bobcat and slowly extend and retract the attachment to ensure there are no leaks. Check for any visible fluid seepage around the connections. If leaks occur, tighten the connections slightly or inspect for damaged seals.

Additional Tips

- Replace Seals: When replacing couplers, consider changing the seals as well to ensure a proper connection and prevent future leaks.

- Consult the Manual: Always refer to the Bobcat operator’s manual for specific instructions and torque specifications for your model.

- Seek Professional Help: If you’re unfamiliar with hydraulic systems or feel uncomfortable replacing the couplers yourself, consult a qualified mechanic or Bobcat service dealer.

safety is paramount when working with hydraulic systems. Wear appropriate safety gear, follow the steps carefully, and don’t hesitate to seek assistance if needed.